Easy Plywood Boat

Living in the middle of Iowa, you wouldn’t expect boats to be a big part of my youth. But in this sea of corn, I grew up fishing on the Mississippi almost every weekend (thanks grandpa). During the weekdays, we would be hitting the water in our ski boat after my dad got off work. Even today, we spend every weekend in our family pontoon boat.

Having always been around boats, it’s been a dream of mine to build a center-console fishing boat. Something in the 27-foot range that can handle off-shore fishing in my retirement years. Now, that’s a long ways off. So, in the meantime, the boat shown here is a good way to test the waters (pun intended) of boat building.

PLYWOOD CONSTRUCTION. In the world of wood boats, there are a few ways to build them. The method we chose for ours is a plywood construction, coated in epoxy resin (to water-proof it). It’s actually pretty straightforward, but there are some angles to tackle. By not applying fiberglass, you remove one of the tedious steps of boat building. What you’re left with is a 14-foot flat bottom boat that’s perfect for exploring small lakes, rivers, and ponds.

Start with the TABLE & BOTTOM

Before we get started, there are a few things I need to point out. First off, the boat is fairly large.

You’ll need space to work and maneuver around the 14-foot boat as you build it. We used a couple of sheets of 3/ 4" MDF as a sacrificial workbench (just make sure the worksurface is flat). Second, you’ll have the flip the boat around, so it will be useful to have a helper on call for some of the awkward (but not heavy) lifting.

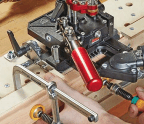

The boat construction starts off by making two sheets of plywood into one long piece. This is done by a traditional boat building joint called a scarf joint. It’s nothing more than long bevels cut on the workpieces and then epoxied together (details ‘1a’

You’re reading a preview, subscribe to read more.

Start your free 30 days